About Us

Precise Design, Meticulous Manufacturing, Detailed Service, and Continuously Meeting Customer Needs

WTL

Inverter Welding Equipment Manufacturer

Inverter Welding Equipment Manufacturer

Shanghai WTL Welding Equipment Manufacture Co., Ltd is a high-tech enterprise specialized in manufacturing and sales of inverter welding equipment. Our company was established in 1993, locates in Pudong New Area (Shanghai) and covers an approximate area of 25,000 m2 with a production capacity of 300,000 units per year. Currently we employ more than 300 people with excellent expertise and passion, including over 30 personnel with master's degrees or higher and senior engineers, as well as more than 20 individuals with intermediate professional titles, technicians account for over 20% of our total workforce. Thanks to the unwavering efforts of all staff over three decades, the company has grown into one of the largest manufacturers of inverter welding machines in China, encompassing three subsidiaries: Nanjing WTL Welding Equipment Co., Ltd, Tianjin Northern WTL Welding Equipment Trading Co., Ltd, and Shanghai WTL Automation Co., Ltd.

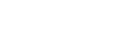

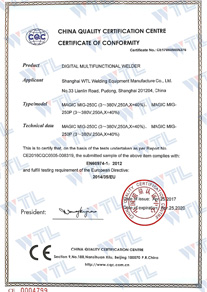

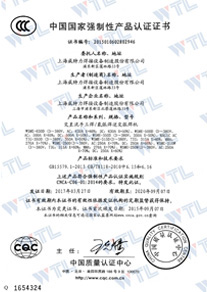

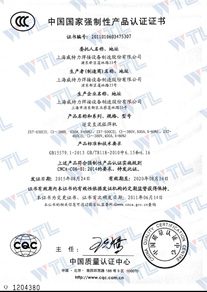

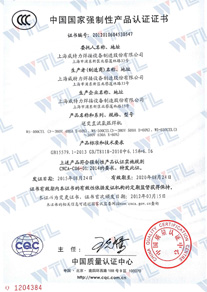

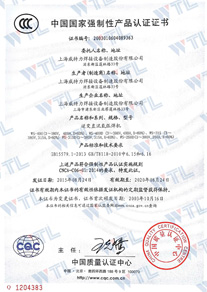

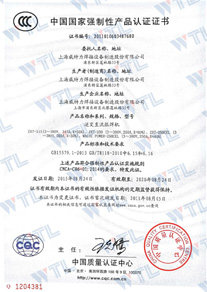

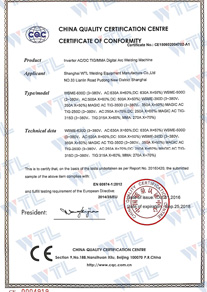

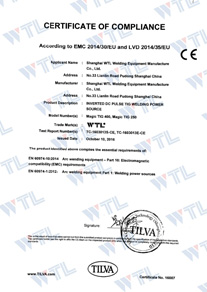

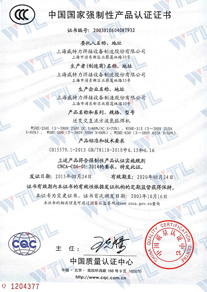

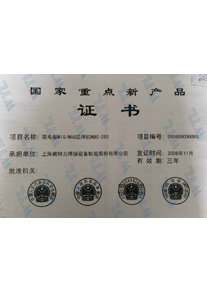

WTL has fully obtained ISO9001: 2015 certification, and all of our products are conformed to CCC, CE, CSA,EMC and RoHS standards. The company owns possess an R&D center with independent intellectual property rights, recognized by Pudong New Area in Shanghai. With multiple national patents in our portfolio, we have also received innovation fund support from the Ministry of Science and Technology. Leveraging our expertise in inverter power supply technology, our digital microcomputer welding machines have garnered recognition from the Shanghai Science and Technology Commission. To date, we hold 12 invention patents, 17 utility model and design patents, as well as 2 software copyrights.

Our products are widely used in industries such as shipyards, petrochemicals, chemicals, machinery, boilers, pressure vessels, electrical and chemical construction, automobiles, bicycles, steel structures, military, and more. With fifteen branches and over thirty agents across China, we have established a comprehensive and effective pre-sale, in-sale, and after-sale service network. Our products are widely recognized and appreciated by both domestic and overseas customers.

1993 1993

year

Founded

25000 25000

㎡

Modernized factory

300 300

thousand

Annual output

Culture

Business Objectives

Corporate Spirit

Quality Policy

Business Objectives

To achieve three leadership positions within the industry:

1.Product Quality Top One; 2.Product Technology Top One; 3.Corporate Management Top One

1.Product Quality Top One; 2.Product Technology Top One; 3.Corporate Management Top One

Corporate Spirit

Integrity as the Base、Unity in Cooperation、Striving for Perfection 、Forging Famous Brands

Quality Policy

Precise Design、Meticulous Manufacturing、Elaborate Service、Sustained Satisfaction of Customer Needs

History

Honorary

Workshop & Equipment

METAL PROCESSING WORKSHOP

METAL PROCESSING WORKSHOP

The Sheet Metal Workshop is a dedicated department under WTL specializing in precision sheet metal processing. It boasts an array of advanced professional equipment, including TRUMPF CNC punching machines, TRUMPF laser cutting machines, Bystronic CNC bending machines, GEMA powder spraying lines, and CNC machining centers. Equipped with high-end production facilities and a professional management team, the workshop guarantees the high precision and quality of our products. Adhering to the principle of “Meticulously Design, Precisely Manufacturing, Exceptional Service, Continuously Meeting Customer Needs”, it serves as an indispensable elite team within our manufacturing system.

SMT

SMT

Equipped with 4 modern and high-efficiency production lines, our SMT Workshop has introduced advanced reflow welding equipment from Germany, high-precision surface mount system, and optical inspection systems from Japan. Adhering to lead-free production processes for solder, components, and equipment, the workshop operates in a dust-free, constant temperature and humidity, and anti-static environment. This enables us to produce up to 1,500 sets of welding machine-compatible circuit boards per day!

ASSEMBLY LINES

ASSEMBLY LINES

Organized by assembly and testing processes for cores, accessories, and complete machines, the workshop boasts 6 advanced production lines capable of completing the entire manufacturing process from assembly, debugging, load aging testing, to packaging in one stop. With full SAP and SIP visualization for both assembly and inspection personnel, it comprehensively enhances assembly efficiency and online quality control capabilities. Guided by the lean manufacturing philosophy, the team operates in a comfortable, healthy, and environmentally friendly workspace, achieving a remarkable production capacity of over a thousand qualified welding machines per day.

配件车间

配件车间

Equipped with a series of high-end production facilities, including precision HAAS machining centers and CNC machines from the USA, as well as BOMA wire cutting machines, high-precision CNC milling machines, drilling machines, and grinding machines, the Accessories Workshop is equipped with the high-precision and high-efficiency processing needs of various complex mechanical components. The workshop’s skilled team, armed with extensive professional knowledge and practical experience, adheres to rigorous work ethics and a strong sense of responsibility, dedicated to producing superior accessories such as welding machine radiators, transformers, and PFCs. With a focus on technological innovation and process improvement, the workshop continuously introduces new production techniques and processes to enhance efficiency, reduce costs, and meet the ever-evolving market demands. The Accessories Workshop boasts a production capacity of 2,000 welding machine radiators per day.